We source from over 30 different countries to ensure our customers receive the best quality materials with fewer supply chain interruptions.

We travel to the fields throughout the year to evaluate the crops and predict market fluctuations. From Lavender in Bulgaria to Amyris in Haiti to the Oranges in Italy. We are grateful to have so many established direct-to-grower partnerships.

Our 120,000 square feet facility South Bend, IN incorporates production, manufacturing, shipping/receiving, and administration.

With tanks up to 240,000 pounds, we can produce essential oil, fragrance, and flavor compounds to support any size from totes, to drums, to pre-packs.

Product safety matters. The desire for natural and environmentally friendly ingredients is becoming more prevalent, which in turn affects formulations. We at Lebermuth are committed to ensuring our products meet the ever-changing regulatory requirements. Between our in-house regulatory team, affiliations and industry associations, we stay current on the regulatory landscape to provide our customers the proper support and certify our products remain in compliance.

We also provide an easy-access Regulatory Document Database that provides the necessary documentation for each of our product item number.

![]()

![]()

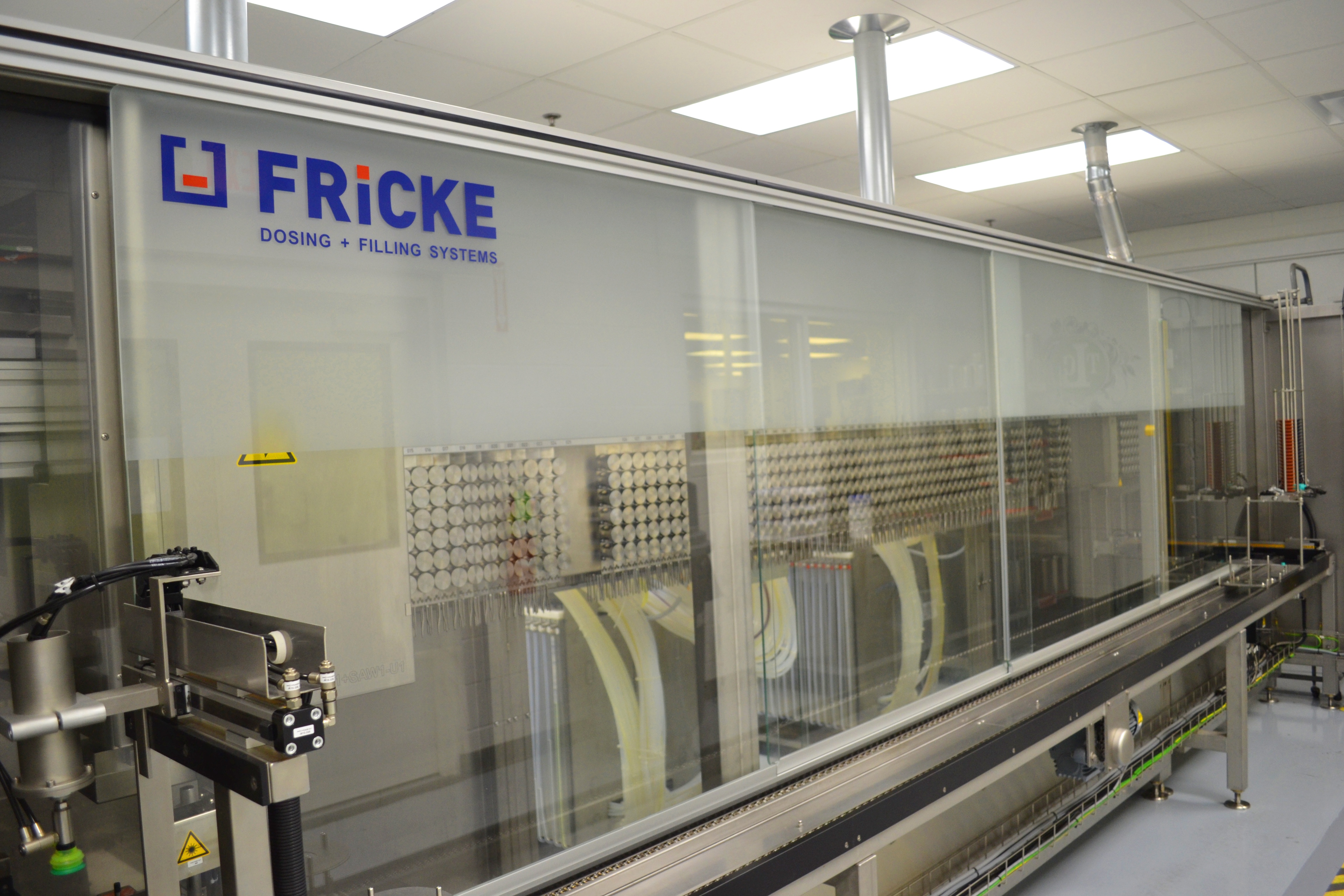

Our blending capabilities include an automated FRICKE Dosing & Filling System which allows us to provide our customers with better accuracy, improved lead times, and less waste.

Using fractional vacuum distillation in our Bremen, IN facility provides us with a more extensive ingredient palette by reducing or removing undesirable components and odors to increase an oil's usability.

Our five distillation units can manage any desired quantity, from smaller batches to rectifying at a rate of 180 kg per hour.

With these distillation capabilities, we're able to create unique products like Tea Tree Oil Heart and Chamomile Coeur. Through innovation in distillation, we're able to offset supply and quality issues, resulting in consistency and lower costs for materials.

We test our products twice to ensure our customers get the best quality.

We test each oil upon arrival to verify it meets the level of quality our customers expect from Lebermuth.

Our applications team tests our products in application so our customers can be confident they receive the best from Lebermuth.

4004 Technology Dr.

South Bend, IN 46628 USA

800.648.1123